Sun 23 May, HHN day 40: Rudder bearing reinstalled. CV joint reinstalled. Found rogue lead-line inside mast.

Forecast is to be a scorcher today and that’s exactly what it turned out to be. 33degc at the peak. But in the tent I measured 49degC, and as I write this at 10:30pm the cabin is still 32 degC. I’ve been in a constant state of melting all day. But I soldiered on, absolutely determined to tick some boxes today.

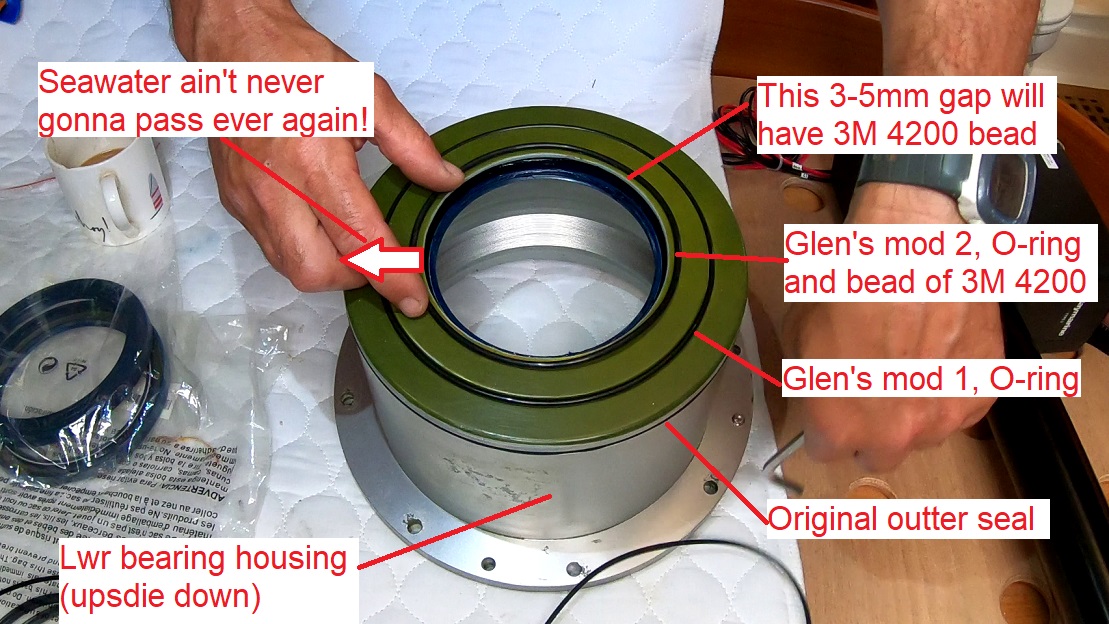

Most of the day was reinstalling the lower rudder bearing so that tomorrow we are ready for the great lift-up, getting the rudder back in. And at last, I can reveal my modifications to the JP3 setup to mitigate any seawater getting in behind the housing.

The O-ring that was supposed to have played this role had been squished out of its slot and broken when it was last installed, presumably at the factory. So seawater had ingressed all the way into the boat causing a lot of corrosion as it did so (you could see from photos when I dismantled it).

I have a replacement for that O-ring, but its slot was badly corroded and I’m not certain my repairs are good enough to make it seal correctly. Anyhow, that O-Ring is now the last of a three O-ring line of defense against the sea.

And I have added 2 more. One O-ring added on the base and another one 3-5mm back from the outside gap which (as the last job of the day) I filled with 3M-4200. Yes, it will have the effect of gluing-in the housing, but I just have to run a knife through the bead of sealant and it should come free OK. But in the meantime, it WON’T get water passed it, you can be sure of that.

In theory, reassembling the roller bearings, and new quad rings inside the sphere is easy. But I took a lot of time doing it, making sure everything was greased correctly and in its place. I ponder for a while whether to put the rudder bearing into the housing, then install the housing in the boat. Or, get the housing in, ensure it is successfully landed, then put the bearing inside last.

I chose the latter, more conservative route. I want to make absolutely certain the housing (with all my modifications) lands perfectly snug where it is designed to be. Getting this wrong could be very costly, so my concentration is at a peak – despite the sweat rolling off me.

Before landing the housing, I have to get the wiper seals in place. These prevent sea water entering the bearing itself. I run around the yard for a while till I find an appropriately solid piece of plywood, in which I cut out a circle the exact size of the seal. This will be my seal-installer, along with a big hammer! With this improvised tool, the seals slips into place perfectly.

The housing then gets installed into the hull and I hold my breath it will fit OK with those added O-rings. But I need not have fretted. It was perfect! The bearing ball is then thrown in (literally… there is no other way) and the top gently screwed in, using anti-seize grease.

With it all in, bolted down and looking good, I almost can’t believe I’ve done it. Especially considering the state it came out a week ago.

Last job, as mentioned above is to go outside and fill that remaining slot with 3M-4200. Then the upper rudder bearing is totally finished. The rudder can now go back in… tomorrow. I’ll need help for that one.

After a spot of lunch, the next job I have a determination about today is reinstalling the CV joint which just came back from rebuild at Authority Marine Propulsion. It is now re-beautified, in a light grey paint.

For its size, it’s a pretty heavy little beasty and I really struggled getting it up the ladder, then down into the engine room. And holding it in place while I get the first 2 bolts in is quite a workout.

After an hour of torture it is installed between the engine and the Aquadrive. I just need to find out what to torque the bolts up to. I’ll have to enquire with someone tomorrow.

I’m pretty glad to be out the engine room. I only have my shorts on, but even those are wet through with sweat. So I go for a welcome cold shower and a break.

Early evening the temperature is about 30degC and it feels wonderful outside compared to the cabin. I’m pretty happy with what I’ve achieved today, so I decide to have a tinker with the endoscope inside the mast.

3 years ago we had a lead-line tied at the top of the mast, which we could not work out where it went to. There was no sign of it lower down. One day we decided to give it an extra hard tug, and it broke. Ever since then we have been imagining a bird’s nest of line somewhere inside the mast.

Well, today I found it. Half way down, and it was quite a bundle. On the end of the line (the end that we could never find) had a string of small weights. Clearly the previous owner had been trying to rethread a lost halyard, and this was what was left of the attempt.

Another job ticked off the list. And this one was pure vintage. I first wrote it on the “to do list” in 2017!

Evening is still hot and steamy inside the boat. And I run any and every fan to try to waft out the hot air and replace with the outside cooler air. Wish I could run the air conditioning.

I had a plan to do that, just for an hour in the evening, to knock the heat out the boat. But annoyingly the water (which I would need as cooling water) has been turned off. Conspiracy? Revenge for my hole digging? Seems a bit odd somehow. I’ve never had it turn off before.

Thank goodness tomorrow looks to be cooler again. I could not survive many days like this one.

But I am very happy with the progress today. Things seem to be coming together at long last.